1. Basic Structure of Lithium Batteries

All lithium batteries are composed of four core components:

Cathode: Determines energy density and cycle performance (ternary lithium uses nickel-cobalt-manganese/aluminum; LFP uses lithium iron phosphate materials)

Anode: Typically made of graphite, responsible for lithium-ion intercalation and deintercalation

Electrolyte: Conducts ions; ternary lithium batteries typically use carbonate-based solvents, while LFP batteries require high-temperature-resistant formulations

Separator: Isolates the cathode and anode, with pore sizes controlled between 10–20μm to balance conductivity and safety

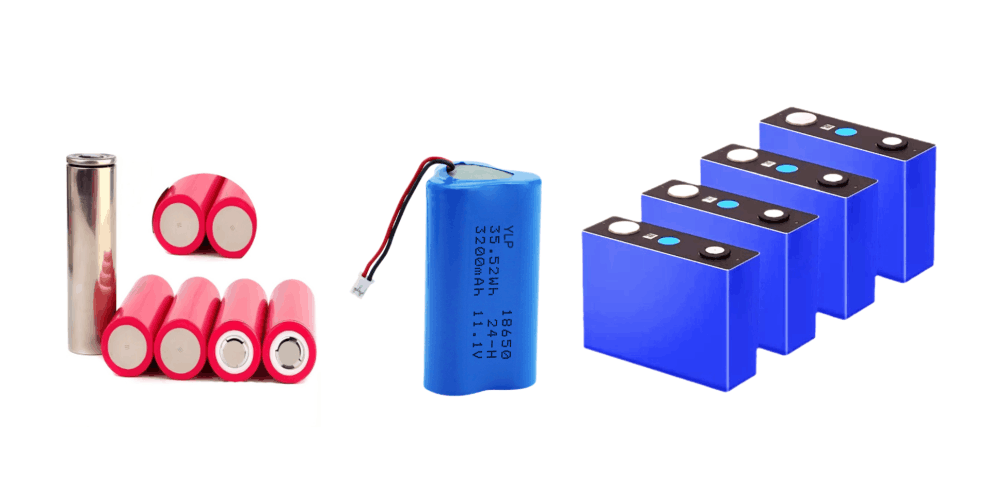

2. Two Main Cell Types Based on Design Orientation:

Power-Type Cells: Focus on high instantaneous power output, featuring low internal resistance (<5mΩ) and high discharge rates (supporting above 10C), suitable for power tools, electric vehicles, etc. For example, ternary lithium cells can achieve peak discharge rates of 20C.

Energy-Type Cells: Emphasize long endurance and stable energy storage, with high energy density (>200Wh/kg). These are widely used in mobile phones, laptops, and energy storage stations. A typical example is the lithium iron phosphate (LFP) cell, which offers a cycle life of over 2,000 cycles.

3. Ternary Lithium vs. LFP Core Parameter Comparison:

| Technical Indicator | Ternary Lithium Battery (NMC) | Lithium Iron Phosphate Battery (LiFePO₄) | Core Differences |

| Nominal Voltage | 3.6V (Platform Voltage: 3.6V) | 3.2V (Platform Voltage: 3.2V) | NMC has 15%-20% higher energy density |

| Energy Density | 180-260 Wh/kg | 90-130 Wh/kg | NMC is more suitable for lightweight devices |

| Cycle Life | 800-1500 cycles | 2000-5000 cycles | LiFePO₄ lifespan is 2-3 times that of NMC |

| Charge/Discharge Temperature | Charge: -25℃ to 60℃ | Charge: 0℃ to 55℃ | NMC has superior low-temperature performance |

| Safety | Thermal runaway temperature >200℃ | Thermal runaway temperature >300℃ | LiFePO₄ has 30% higher high-temperature tolerance |

| Typical Weight | 21700 cell: ~50g | Equivalent capacity cell: ~65g | NMC's lightweight design suits portable devices |

1. Electric Transportation Sector

(1) Electric Vehicles

Ternary Lithium Advantages: More stable low-temperature range, with less than 25% range degradation at -10°C, ideal for cold northern regions; fast charging support with 3C rate (80% charge in 30 minutes), meeting high-frequency charging needs.

LFP Advantages: Longer cycle life—retains 85% capacity after 5000 cycles, suitable for high-frequency use cases like taxis and ride-hailing services; lower cost—material cost is 30% lower than ternary lithium, reducing battery pack expenditure.

(2) Power Tools / Drones

Core Requirements: High pulse current (>10C discharge), lightweight.

Best Choice: Many ternary lithium power cells support 25C or higher discharge rates with <5% voltage fluctuation at startup, helping prevent drone control failures.

2. Energy Storage System Solutions

(1) C&I Energy Storage Stations

LFP First Choice:

· Long-cycle economics: Over 2000 cycles; LCOE is 40% lower than lead-acid batteries.

· Prioritized safety: Passed UL9540A thermal runaway test; paired with BMS for ±0.1°C temperature monitoring.

· Typical Configuration: 256-series 120Ah LFP modules; scalable to 1MWh via parallel connections, suitable for PV/grid hybrid storage.

(2) Home Storage / Backup Power

Ternary Lithium Advantages:

· Compact and easy to install: 30% smaller volume than LFP for the same capacity, ideal for wall-mounted residential systems.

· Low self-discharge: <3%/month, ensuring longer standby and reliable power during outages.

3. Consumer Electronics and Smart Home

(1) 3C Devices (Phones / Laptops)

Ternary Lithium Dominates:

· High energy density: 3.7V nominal voltage; 3000mAh cell is only 4.5mm thick, suitable for ultra-thin designs.

· Fast charging compatibility: Supports PD/QC protocols, 18W charging reaches 60% in 30 minutes.

(2) Smart Appliances (Robot Vacuums / Security Cameras)

LFP Potential:

· Wide temperature operation: Stable discharge from -20°C to 60°C, outdoor cameras can still run 8 hours in northern winters.

· Deep discharge protection: Supports cut-off at 2.5V to prevent over-discharge damage and extend device lifespan.

Q1: Why is LFP more suitable for energy storage stations?

A1: It's all about full-cycle economics:

Long cycle life: 5000 cycles vs. 1000 for ternary lithium, reducing replacement costs by 60%.

Higher safety: 100°C higher thermal runaway threshold, 3× safer with BMS.

Material stability: LFP cathode material price fluctuation <10%, while ternary lithium (especially cobalt) often exceeds 50%.

Q2: Can ternary lithium batteries operate at -40°C?

A2: Standard ternary lithium retains only 30% capacity at -40°C; customized solutions can meet such needs.

Q3: Can ternary lithium and LFP be mixed?

A3: Direct mixing is prohibited! Their voltage platforms and charge-discharge characteristics differ greatly. Forced series connections may cause overcharge of ternary cells and BMS imbalance.

Correct approach: Use a single cell type per pack, with BMS for independent management.

Ternary lithium and LFP batteries are not competitors but complementary solutions:

For energy density and low-temperature performance: Choose ternary lithium (EVs, drones, 3C devices)

For long lifespan and cost control: Choose LFP (storage stations, commercial vehicles, backup systems)

As a professional battery solution provider, Yilai Technology has focused on battery innovation for over a decade, offering:

Cell Customization: Tailored to project needs, balancing performance and cost.

System Integration: End-to-end services from design to debugging, ensuring stable and efficient operation.

Extreme Environment Adaptation: Custom solutions for harsh conditions like extreme cold or heat, ensuring battery reliability.

Contact Us:

Tel: 0755-29300814

WhatsApp: +86 158 1850 9713

Email: tracy.qin@yilaipower.com

Add: Building B, Tianxia International Center, No. 8 Taoyuan Rd, Nanshan, Shenzhen, PRC