Lithium batteries are now widely used in mobile phones, electric vehicles, energy storage equipment, and various electronic products, but many people are unaware of the role of the lithium battery protection board. This article will help you understand what a protection board is, why it's important, and under what circumstances it can be skipped, ensuring the safe use of lithium batteries.

Lithium Batteries' "Sensitive Nature"

Lithium batteries are very sensitive to voltage, current, and temperature:

Overcharging Risk: When the voltage exceeds the safety value (e.g., over 4.2V for ternary lithium batteries), the battery reacts violently, which could cause swelling, leakage, or even a fire, just like an overinflated balloon bursting;

Overdischarge Damage: When the charge drops too low (below 2.5V), it damages the internal structure of the battery, significantly shortening its lifespan, similar to a phone that won't charge after over-discharging;

Overcurrent Risk: If the current exceeds the safe range (e.g., using 4A current to discharge a 2000mAh battery), the battery will overheat quickly, potentially causing a short circuit, just like an overloaded wire that heats up.

The Four Protective Functions of the Protection Board

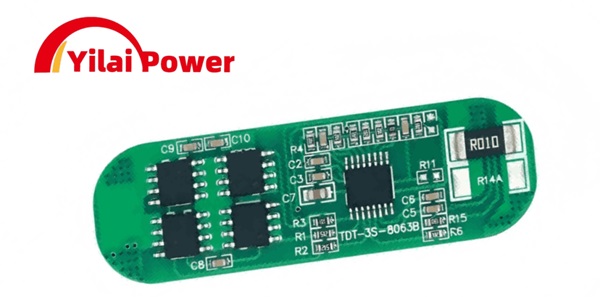

The protection board is a small circuit board, constantly guarding the battery like a "safety guard":

Overcharge Protection: Automatically cuts off charging when the voltage is too high, preventing the battery from "bursting."

Overdischarge Protection: Stops discharging when the charge is too low, avoiding the battery from "dying."

Overcurrent / Short-Circuit Protection: Quickly cuts off the power in case of abnormal current, preventing short-circuit fires.

Overheat Protection: Limits usage when the temperature is too high, avoiding the battery from "overheating."

Space Limitations

Small devices, such as smartwatches or wireless earphones, have very limited internal space. The protection board may take up 30% of the space, much like a small pocket that can't hold a large wallet, so it's removed.

Cost Control

For low-profit products, such as toys or low-end electronics, removing the protection board can reduce costs by 10%-20%, which is suitable for mass production when controlling budgets.

External Protection

Some devices come with their own protection features:

Mobile phone chargers have built-in overcharge protection;

Large energy storage systems monitor everything with a centralized BMS (battery management system) and do not require individual protection boards for each battery.

Real-World Warnings

Overcharge Fires: A user left a battery without a protection board charging overnight, and the next day, the battery was swollen and smoking — like leaving a faucet on all night causing a flood.

Overdischarge and Scrap: After the outdoor device's charge is exhausted, continued use causes the battery to be completely unchargeable — similar to a phone that can't turn on after it has automatically shut down.

Short-Circuit Burns: A key accidentally touched the positive and negative terminals of a battery without a protection board, instantly heating up to 60°C — similar to the dangerous temperature of a short-circuited wire.

Data Comparison: With Protection Board vs. Without Protection Board

| Metric | With Protection Board | Without Protection Board |

|---|---|---|

| Overcharge Probability | Extremely low (about 1 time per 100,000 charges) | Significantly higher (about 1 time per 1,000 charges) |

| Battery Lifespan | Longer (typically 3-5 years, over 1,000 cycles) | Significantly shorter (typically 1-2 years, around 500 cycles) |

| Safety Incident Rate | Very low (industry typical value < 0.01%) | Significantly increased (industry typical value > 0.5%) |

At Yilai Power, we take the safety risks of lithium battery applications very seriously. Therefore, we will only consider offering lithium battery solutions without a protection board after extremely strict assessments and tests, ensuring that multiple safety measures are in place.

Low-Risk, Small Capacity Applications

For batteries under 50mAh (such as those in remote controls or calculators), which have low power usage and slow discharge rates, similar to bicycles not needing seatbelts, but must meet the following conditions:

Stable current, no sudden increase;

Charging time can be controlled (not exceeding 2 hours).

Professional-Grade External Protection

Large industrial equipment may carefully skip the protection board if it meets the following conditions:

Equipped with a centralized BMS (accuracy of ±5mV);

Uses fire-resistant housing (meets UL94V-0 standard);

Has a temperature monitoring system (error ±2°C).

Use of Safe Batteries

Choose lithium iron phosphate (LiFePO4) batteries, which have a thermal runaway temperature > 210°C (for ternary lithium batteries, it's 150°C), similar to selecting a safer model, but still requires:

Over 100 charge/discharge cycles of testing;

Paired with a PTC thermistor (automatically disconnects power at 85°C).

Passive Safety Components

Add PTC thermistors, fuses, or voltage regulators to provide basic protection. For example, a PTC thermistor increases resistance when the temperature is too high, cutting off the current, similar to a fuse in a home electrical system.

Smart Charging System

Some smart chargers have overcharge and overcurrent protection features, which can replace some functions of the protection board. For example, a smartphone charger will automatically adjust the current based on the battery's status, reducing the risk of overcharging.

The Future of Solid-State Batteries

Solid-state batteries, which are set to be mass-produced in 2027, use solid-state electrolytes and are not flammable, significantly improving safety. This may reduce the reliance on protection boards in the future, but basic protection will still be required to prevent overcharging.

Consumer Decision Guide

Consider the Usage

Mobile phones, electric vehicles, laptops, and other commonly used/high-power devices: Must use batteries with a protection board, safety first;

Remote controls, small calculators, and low-power sensors: May cautiously choose batteries without a protection board, but ensure the brand is reputable and usage conditions are safe.

Choose the Battery Type

Ternary lithium batteries (high energy density): Always pair with a protection board;

Lithium iron phosphate batteries (better thermal stability and safer): Can consider skipping the independent protection board under professional design and multiple safeguards but still require basic protection.

Check Safety Certifications

Ask whether overcharge protection is present and whether the product has passed UL, CE, or other certifications, much like checking the safety inspection report for food.

Enterprise Procurement Considerations

| Scenario | Protection Board Recommendation | Safety Optimization Plan |

|---|---|---|

| Consumer Electronics | Must be equipped | Prioritize choosing finished battery modules with integrated protection ICs |

| Industrial Equipment/Tools | Recommended | Consider lithium iron phosphate batteries with basic protection circuits or redundancy designs |

| Large-Scale Energy Storage Systems | Must be equipped | Use centralized BMS with redundant individual protection boards |

Q: Can the protection board be removed from the battery?

A: Strongly discouraged. Removing the protection board easily damages the internal structure of the battery (such as weld points and wiring) and immediately loses all protective functions, significantly increasing the risks of overcharging, overdischarging, and short circuits. Non-professional handling can make the situation worse.

Q: Can a smart charger fully replace a protection board?

A: No, it cannot fully replace it. A smart charger mainly provides protection during the charging phase (such as overcharging or overcurrent) but cannot monitor overdischarge, overcurrent, or localized temperature abnormalities during discharge. The protection board offers comprehensive protection throughout the entire cycle (charging, discharging, idle).

Q: How can a lithium battery without a protection board ensure safety?

A: It must meet the following strict conditions: ① Use batteries with higher intrinsic safety (such as lithium iron phosphate); ② Must pair with reliable passive protection components (such as PTC, fuses); ③ Products must undergo rigorous testing (including but not limited to charge/discharge cycles, performance under various temperature and humidity conditions, short circuits, crushing, puncturing, etc.), and be evaluated and certified by professional organizations.

Q: Does the protection board's lifespan match that of the battery?

A: A well-designed, high-quality protection board can last 5-9 years (typically measured by MTBF - Mean Time Between Failures), matching the cycle life of mainstream lithium batteries. However, physical impacts, long-term exposure to high temperatures and humidity will shorten the protection board's lifespan.

Q: Are batteries without a protection board suitable for any professional scenarios?

A: They are only suitable for specific scenarios with well-established and high-reliability external protection measures, such as large-scale energy storage systems monitored by centralized BMS, industrial equipment with multiple hardware redundancy protections, or special battery applications using solid electrolytes or other new safety technologies. These solutions must be designed by professional teams after thorough system-level design and risk assessments and should not be used in regular scenarios.

Lithium battery protection boards are a crucial barrier to ensure user safety and equipment reliability. Whether to omit the protection board is not a simple matter of cost or space considerations, but rather a complex decision that requires rigorous risk assessment, professional design capabilities, and multiple safety measures.

For ordinary consumers: It is strongly recommended to prioritize choosing lithium battery products with qualified protection boards, as this is the most convenient and fundamental safety assurance.

For industrial and professional fields: The omission of the independent protection board can only be considered when the strict conditions outlined in Section IV of this article are met, and after systematic evaluation and verification by professional teams such as Yilai Power. Safety must always be the top priority.

Remember: Safety is never a trivial matter. A scientific understanding of lithium battery characteristics and the proper use of protective measures will ensure that lithium battery technology can reliably serve our lives and work.

For more information on lithium battery safety design, BMS solutions, or customized battery services, please feel free to contact the Yilai Power technical team. We are committed to providing you with safe and reliable energy solutions.