As a seasoned professional with years of experience in the lithium battery industry, serving OEMs, system integrators, and procurement teams across Europe and North America, we’ve observed a clear trend in recent years: an increasing number of B2B buyers are proactively specifying 21700 batteries during the product design phase, rather than merely evaluating them as an alternative to 18650 cells.

This shift is not driven by trends or marketing, but by core needs for improved engineering efficiency, optimized total cost of ownership, and guaranteed regulatory reliability.

However, many buyers still have fragmented understanding of 21700 batteries:

• Only knowing it is "bigger than the 18650"

• Mistakenly assuming "higher capacity equals better"

• Struggling to define what "high-quality" truly means in a B2B context

1. From an engineering and procurement perspective, what is the true core value of 21700 batteries?

2. Are 18650 and 21700 batteries truly interchangeable?

3. What defines a high-quality 21700 battery for professional applications?

Additionally, we will break down real-world application cases, performance data, selection logic, and common procurement pitfalls, ensuring this guide genuinely helps you make better decisions—not just rank in search results.

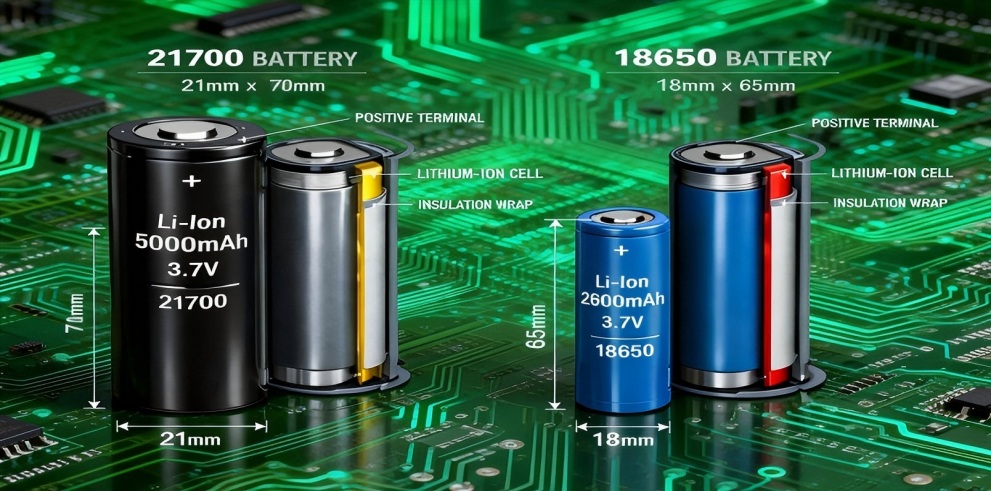

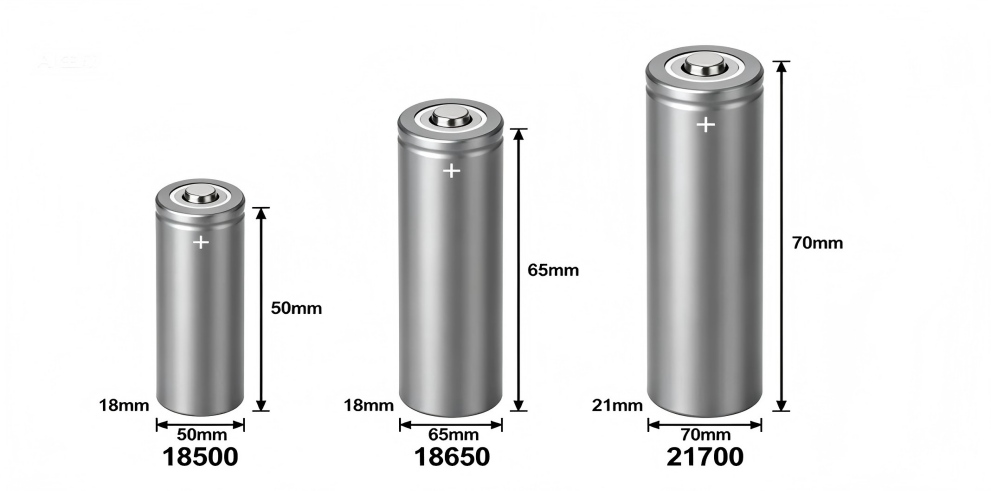

The 21700 battery follows the standardized cylindrical cell naming system used in the lithium-ion industry, where the numbers directly correspond to the cell’s physical dimensions:

• 21: Diameter in millimeters

• 70: Length in millimeters

In comparison, the classic 18650 battery is 18mm in diameter and 65mm in length. The launch of the 21700 specification is to break through the performance bottleneck of the 18650 battery. By expanding the volume of active materials and optimizing the heat dissipation area, the 21700 battery achieves higher single-cell capacity, stronger discharge current, and better overall efficiency of battery packs.

In practical applications, "21700" represents a paradigm shift in lithium-ion technology:

• Fewer cells required per battery pack

• Higher energy density per cell

• Superior thermal and electrical efficiency at the system level

This is why many OEMs no longer ask, "Is the 21700 bigger?" Instead, they inquire: "Can the 21700 enable us to redesign the entire power system more efficiently?"

Engineering Insight: The advantage of 21700 cells lies not only in higher individual capacity but also in the reduced number of cells needed per pack. This directly decreases the number of interconnections and weld points, thereby lowering failure risks.

The 18650 battery has been the mainstream cylindrical lithium battery for decades, but with the upgrade of industrial equipment, energy storage systems and electric mobility products, its limitations are gradually emerging:

• Need a large number of cells to meet high-power and high-capacity demand, leading to complex battery pack assembly

• High assembly complexity increases production and maintenance costs

• Dense cell arrangement leads to heat dissipation bottlenecks under high discharge rate

The 21700 battery perfectly solves these pain points while retaining the mature cylindrical structure and automated production compatibility of the 18650 battery. It is an iterative upgrade rather than a subversive replacement.

The 21700 format was introduced primarily to solve three key limitations that became increasingly apparent with 18650-based systems:

Pack Complexity: Large battery packs built with 18650 cells require hundreds or even thousands of weld points, each representing a potential failure risk;

Energy Density Ceiling: Incremental improvements in chemistry could no longer compensate for the limited cell volume;

Thermal Management Constraints: High-current applications exposed the heat dissipation limits of densely packed 18650 cell arrays.

By increasing cell volume, the 21700 format allows manufacturers to:

• Utilize thicker electrodes

• Optimize internal current paths

• Enhance heat dissipation across the cell body

The result is higher usable energy, not just higher nominal capacity.

For enterprise buyers, "21700" signifies:

• Lower system-level failure risk

• Simpler battery pack architecture

• Greater scalability for future product iterations

In regulated industries—especially medical and industrial equipment—this system-level reliability is often more valuable than marginal gains in cell capacity.

Although both are cylindrical lithium-ion cells, 18650 and 21700 batteries differ fundamentally in performance, design implications, and application suitability.

Parameter | 18650 Battery | 21700 Battery |

Diameter | 18 mm | 21 mm |

Length | 65 mm | 70 mm |

Typical Capacity | 2500–3500 mAh | 4000–6000 mAh |

Energy Density | Lower | Higher |

Pack-Level Cell Count | Higher | Lower |

From a B2B system design perspective, the most critical difference lies not in the cells themselves, but in how the cells influence the overall battery pack architecture:

• Fewer cells reduce BMS (Battery Management System) balancing complexity

• Lower interconnection resistance improves efficiency

• Fewer assembly steps reduce long-term defect rates

On paper, this appears to be a simple scaling issue. In practice, it completely transforms pack design logic.

When comparing 18650 and 21700 batteries, professional buyers should focus less on individual cell specifications and more on pack-level efficiency:

• Fewer cells → Fewer weld points

• Fewer weld points → Lower internal resistance

• Lower internal resistance → Less heat generation under load

• Less heat → Longer cycle life and safer operation

For high-reliability systems, this cascading effect is often the decisive factor.

In high-discharge or continuous-load applications, 21700 batteries typically demonstrate:

• More stable temperature rise curves

• Slower heat accumulation

• Better compatibility with passive cooling designs

This makes them particularly suitable for:

• Medical mobility equipment

• Industrial automation devices

• Energy storage modules with long duty cycles

Despite the 21700’s advantages, 18650 batteries are not obsolete and remain relevant in the following scenarios:

• Products with extremely tight space constraints

• Legacy designs that cannot be retooled

• Applications where minimizing upfront tooling costs is critical

The key decision logic is not "Which is better?" but rather "Which format aligns with our system priorities and lifecycle goals?"

Procurement Insight: The justification for switching from 18650 to 21700 often stems not from capacity alone, but from lower total cost of ownership at the battery pack level.

Application Sector | 21700 Battery Suitable Scenarios | 18650 Battery Suitable Scenarios | Core Selection Logic |

Medical Devices | Portable monitors, infusion pumps, emergency diagnostic equipment | Small portable medical accessories, legacy medical devices | 21700: Fewer cells simplify certification; superior thermal stability meets compliance requirements; 18650: Suitable for space-constrained small devices |

Industrial Equipment | AGV/AMR robots, industrial controllers, high-power backup power | Small sensors, low-power industrial control modules, legacy production line equipment | 21700: High discharge capability + low maintenance needs for continuous loads; 18650: Cost-sensitive + low-power demand scenarios |

Energy Storage Systems | Modular ESS, UPS systems, distributed energy nodes | Small household energy storage, portable emergency power supplies | 21700: High energy density + easy scalability for large-scale storage; 18650: Low capacity requirements + budget constraints |

Consumer Electronics | High-end portable power stations, professional photography equipment, high-power handheld tools | Laptops, small power banks, standard digital devices | 21700: Long runtime + fast charging for high-power consumer products; 18650: Mature supply chain + space-constrained requirements |

Electric Mobility | Light electric vehicles, e-scooters, low-speed mobility devices | Electric toothbrushes, small mobility tools, traditional electric toys | 21700: High capacity + resistance to degradation for frequent use; 18650: Low power consumption + cost-effectiveness for small mobile devices |

• 21700 Battery Core Applications:

Portable patient monitors, infusion pumps, emergency diagnostic equipment.

Key Advantages: Longer runtime reduces charging frequency for healthcare staff; fewer cells simplify ISO 13485 compliance certification; excellent thermal stability meets the rigorous requirements of IEC 62133 for medical devices.

Typical Case: A European medical device manufacturer adopted 21700 battery packs for mobile ultrasound equipment, increasing runtime by 40% and reducing failure rates by 35%.

• 18650 Battery Core Applications:

Small medical accessories (e.g., portable blood glucose meters), unupgraded legacy medical devices.

Key Advantages: Compact size fits miniaturized device designs; mature supply chain ensures stable supply; no upfront mold modification costs required.

• 21700 Battery Core Applications:

AGV/AMR autonomous guided robots, industrial controllers, high-power backup power supplies.

Key Advantages: High discharge current supports dynamic robot loads; stable heat dissipation during continuous operation; fewer connection points reduce failure risks in industrial environments; maintenance intervals extended by over 50%.

Typical Case: An automotive factory implemented 21700 battery packs for AGVs, increasing single-charge runtime from 8 to 12 hours, reducing charging frequency, and improving production efficiency by 30%.

• 18650 Battery Core Applications:

Small industrial sensors, low-power industrial control modules, legacy production line equipment.

Key Advantages: Cost advantages for low-power requirements; fits battery compartment designs of legacy equipment; no need to redesign existing circuits.

• 21700 Battery Core Applications:

Modular Energy Storage Systems (ESS), enterprise-grade UPS, distributed energy nodes.

Key Advantages: High energy density per module reduces storage cabinet footprint; modular design enables on-demand scalability; long cycle life suits long-duration storage scenarios (e.g., solar supporting storage).

Typical Case: A commercial park adopted 21700 storage modules, reducing cell count by 30% compared to 18650 solutions, lowering system failure rates by 28%, and decreasing levelized cost of energy by 15%.

• 18650 Battery Core Applications:

Small household energy storage, portable emergency power supplies, desktop UPS.

Key Advantages: Cost-effective for personal or low-power scenarios; lightweight and easy to transport; proven reliability through market validation.

• 21700 Battery Core Applications:

High-end portable power stations, professional photography equipment, high-power handheld power tools, light electric vehicles.

Key Advantages: High capacity supports long runtime (e.g., 50% longer runtime for portable power stations); excellent fast-charging performance (80% charge in 30 minutes); strong resistance to degradation for frequent use.

• 18650 Battery Core Applications:

Laptops, standard power banks, electric toothbrushes, small electric toys.

Key Advantages: Low cost due to mature supply chain; compact size fits slim consumer electronics designs; meets daily usage needs of low-power devices.

This is the most commercially critical yet misunderstood question. There is no single "best" 21700 battery for all applications—quality must be evaluated based on consistency, reliability, and suitability for your specific use case.

In consumer markets, "high-quality" often means:

• Highest advertised capacity

• Most famous brand name

In B2B markets, quality is defined very differently.

Based on our experience supplying OEM customers, a high-quality 21700 battery should deliver:

• Predictable performance

• Long-term consistency

• Full compliance and traceability

Quality Factor | Importance for B2B Buyers |

Capacity Consistency | Ensures predictable runtime and simplifies system calibration |

Internal Resistance Control Precision | Reduces heat generation and improves series-parallel balancing |

Formation & Aging Processes | Prevents early capacity degradation in field use |

Traceability | Critical for audits, warranty analysis, and regulatory compliance |

Cycle Life at Partial Depth of Discharge (DoD) | Reflects real-world industrial usage patterns |

High-quality 21700 batteries should exhibit:

• Minimal capacity deviation

• Tight internal resistance (IR) distribution

• Stable voltage curves across batches

For battery packs, consistency is often more important than absolute capacity.

Marketing cycle life figures are often measured under ideal laboratory conditions. Professional buyers should proactively ask:

• At what discharge rate was the cycle life tested?

• What temperature conditions were used?

• At what depth of discharge (DoD) was the testing conducted?

A realistic benchmark for high-quality 21700 cells is:

• 800–1500 cycles, depending on chemistry and operating profile

There is no single "best" chemistry—selection depends on requirements:

• NMC (Nickel-Manganese-Cobalt): Balanced energy density and cycle life

• NCA (Nickel-Cobalt-Aluminum): Higher energy density, stricter thermal management requirements

• LFP (Lithium Iron Phosphate, 21700 format): Lower energy density, excellent safety and longevity

The optimal choice depends on risk tolerance and operating environment, not just specification numbers.

Many B2B buyers assume that selecting a globally renowned brand guarantees quality. In reality, a high-quality 21700 battery is determined by:

• Batch consistency, not brand reputation

• Matching between cells in the same pack

• Supplier willingness to share test data and Statistical Process Control (SPC) reports

For OEMs, a well-controlled industrial-grade 21700 cell with full data transparency often outperforms a consumer-optimized cell used outside its intended design parameters.

Metric | 21700 Battery | 18650 Battery |

Energy Density | 260–280 Wh/kg | 240–260 Wh/kg |

Typical Cycle Life | 1000+ cycles | 800+ cycles |

Thermal Stability | Higher | Moderate |

Pack Complexity | Lower | Higher |

Maximum Single-Cell Discharge Current | 20–30A | 10–20A |

Nominal Voltage | 3.6–3.7V | 3.6–3.7V |

Note: Cycle life tested at 25℃, 1C/1C charge-discharge rate, 2.5–4.2V voltage window (80% capacity retention)。

When sourcing 21700 or 18650 batteries for B2B applications, we recommend a scenario-adaptive + system-level evaluation approach for supplier selection:

• Clarify core requirements: Prioritize defining four key dimensions—"space constraints," "power requirements," "compliance needs," and "budget range";

• Verify supplier capabilities: Can they provide scenario-specific test data (e.g., cycle life under high/low temperature conditions), long-term supply stability documentation, and compliance certification files;

• Evaluate additional value: Do they offer battery pack integration solutions, BMS matching support, and after-sales technical services;

• Reference industry standards: Prioritize suppliers complying with core standards such as IEC 62133, UN 38.3, and UL.

For further technical reference, you may consult:

• IEC lithium battery standards

• UN 38.3 transportation testing requirements

• Industry-specific compliance standards (e.g., ISO 13485 for medical applications)

A1: With proper BMS design and pack architecture, 21700 batteries typically offer superior thermal stability at the system level, especially in high-power, long-duration operation scenarios. However, 18650 batteries have also undergone long-term market validation for safety in mature applications.

A2: General core certifications include UN 38.3 (transport safety), IEC 62133 (battery safety), and UL standards (electrical safety); medical applications require additional compliance with ISO 13485 (quality management system), while energy storage applications must meet IEC 62619 (energy storage system safety).

A3: At the individual cell level, 21700 batteries are typically more expensive; however, at the system level, 21700 often offers lower total cost of ownership for high-power, long-cycle applications (e.g., industrial equipment, energy storage systems) due to reduced assembly costs, maintenance expenses, and failure losses.

A4: The difference is minimal, typically ranging from 100–500 units depending on configuration complexity, certification requirements, and supplier production capacity. MOQs for legacy 18650 battery packs may be lower, with some suppliers supporting small-batch replenishment.

A5: Three-step decision process:

Check space: Does the device battery compartment accommodate the 21700 dimensions (21mm diameter, 70mm length);

Evaluate power: Do you need high discharge current (≥20A) or long runtime (≥10 hours of continuous operation);

Consider planning: Do you have long-term product iteration plans (21700 is better suited for future expansion).

Choosing between 21700 and 18650 lithium-ion batteries is essentially a precision matching of product demand and technical characteristics, not a simple choice of "better or worse".

The 21700 battery is an upgraded solution for high-power, large-scale and high-reliability scenarios: it brings higher energy density, lower system complexity and longer service life, and its core value is to optimize the whole life cycle cost and reduce system failure risks for B2B customers.

The 18650 battery is still an irreplaceable classic choice: it has mature supply chain, stable quality and cost advantages, and is the best solution for small size, low power and cost-sensitive scenarios.

The most important step in battery selection is to clarify your core needs - space constraints, power demand, compliance standards and budget, and then select the most suitable battery type based on these needs. Early cooperation with professional battery suppliers can effectively reduce R&D risks, shorten product certification cycles and optimize long-term operation costs.

If you need customized selection suggestions or technical solutions for your specific application scenarios, welcome to contact our professional technical team for one-on-one in-depth consulting services.

© Yilai Power – Professional Custom Lithium Battery Solutions