With the rapid development of the new energy industry, lithium batteries, as the core medium for energy storage and conversion, have always been the focus of industry attention due to their technological iteration and process upgrades. Among them, soft-pack lithium batteries have gained increasing popularity across fields such as consumer electronics, new energy vehicles, and energy storage systems, due to their excellent safety performance, flexible design, and high energy density.

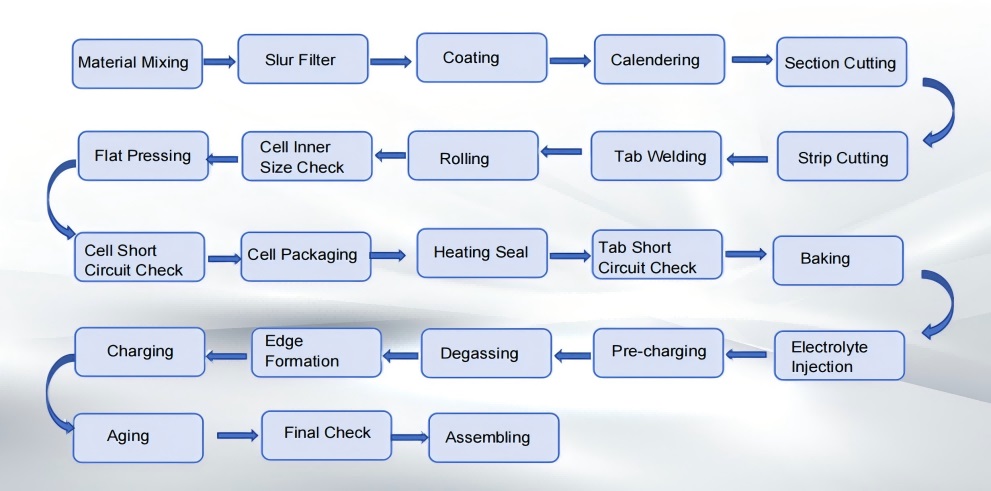

As a company focused on lithium battery technology research and production, Yilai Power understands the decisive impact of process details on product performance. From material selection to precision control of key processes such as slurry preparation, coating, and winding, every step of the process innovation aims to enhance battery safety, consistency, and cycle life. This article will systematically analyze the key manufacturing processes and core technical points of soft-pack lithium batteries, providing you with an in-depth understanding of the technology behind this efficient energy carrier.

Common lithium batteries are roughly classified into the following three types based on shape:

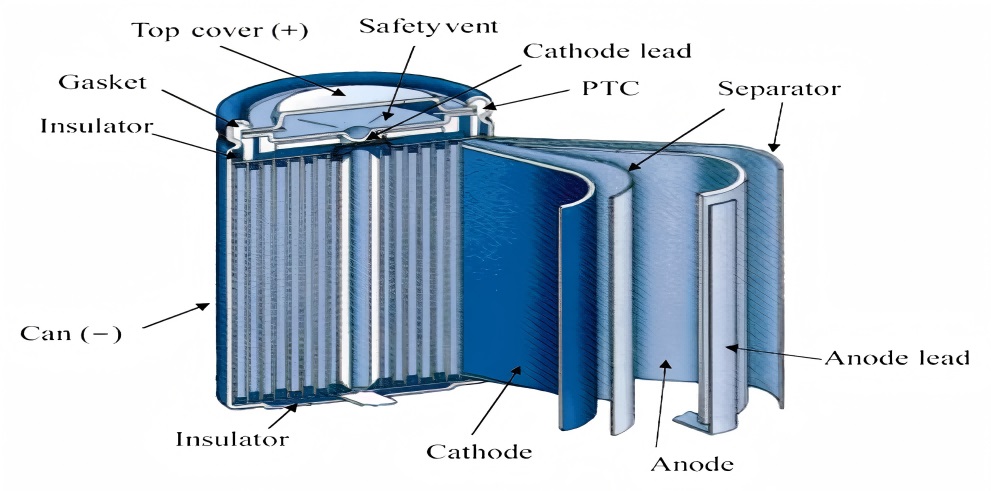

Cylindrical Lithium Batteries

Manufacturing Process: Winding.

Advantages: Mature automated production process, low cost, strong battery pack consistency, high energy density.

Disadvantages: Low individual capacity, high requirements for BMS and heat dissipation systems.

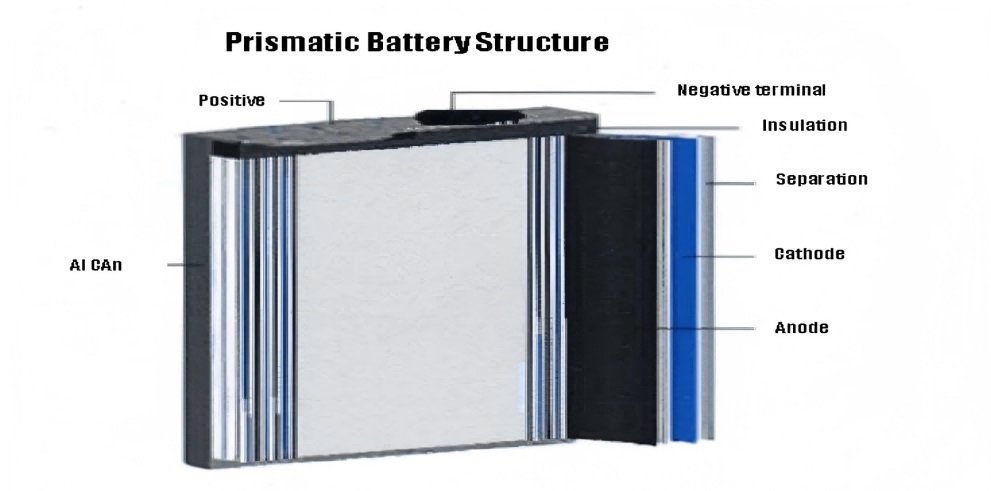

Prismatic Lithium Batteries

Manufacturing Process: Winding, Stacking.

Advantages: The shell (steel/aluminum) provides better physical protection for the cells than soft-pack and cylindrical batteries, making them safer under mechanical abuse (such as compression or impact).

Disadvantages: Heavy shell, limited energy density of the battery pack, too many models, difficult to standardize manufacturing processes.

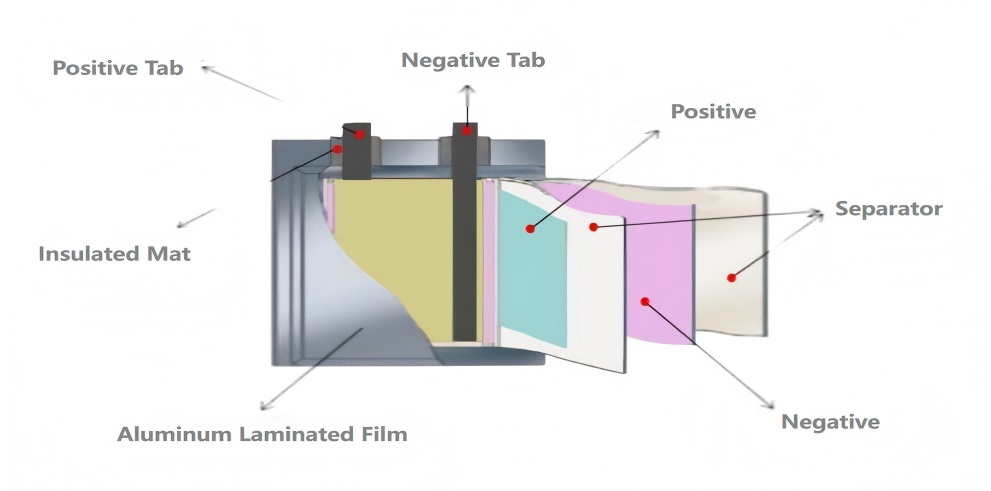

Soft-Pack Lithium Batteries

Manufacturing Process: Stacking, Winding.

Advantages: Excellent safety performance, lightweight, high specific capacity, low internal resistance, flexible design, and under reasonable design, cycle life can be superior to hard-shell batteries of the same type.

Disadvantages: Relative difficulty in consistency control compared to hard-shell batteries, which can be significantly improved through advanced processes (such as Z-fold stacking + high-precision winding), higher cost, and relatively easier to experience leakage.

Positive electrode materials play a crucial role in the lithium battery industry chain, being a key upstream component. The upstream lithium battery industry chain can be broadly divided into four main parts: positive electrode materials, negative electrode materials, separators, and electrolytes. Among these, the positive electrode material is the decisive factor for the electrochemical performance of the battery, impacting the battery's energy density and safety. The cost of positive electrode materials is also relatively high, accounting for around 40% of the cost in ternary lithium batteries and about 30% in lithium iron phosphate (LFP) batteries.

Yilai Power focuses on the development of lithium batteries and adopts differentiated positive electrode systems for different applications. In the consumer electronics sector, high-capacity ternary materials (NCM523) are primarily used, while the energy storage field focuses on lithium iron phosphate (LFP) for a balance of safety and cycle life, offering a variety of high-performance lithium battery solutions.

Graphite is currently the most commercially developed negative electrode material for lithium batteries. Natural and artificial graphite, due to their layered structure, can facilitate the insertion and extraction of lithium ions, offering good cycling stability and relatively low cost. Its theoretical specific capacity is 372 mAh/g, and its low voltage platform makes it suitable for high-energy-density batteries. Lithium-ion batteries convert chemical energy into electrical energy through the intercalation and de-intercalation of Li⁺ ions between the positive and negative electrodes. The active components of both the positive and negative electrodes serve as the energy storage carriers.

The core of slurry preparation lies in dispersing the active material, conductive agent, binder, etc., in a solvent in specific proportions to form a homogeneous slurry. During this process, both physical dispersion and chemical stabilization mechanisms work together to ensure full mixing and stable suspension of the components. For the positive electrode, N-Methyl-2-pyrrolidone (NMP) solvent is used (suitable for the PVDF binder), and for the negative electrode, aqueous solvents are used (compatible with the SBR binder), reducing the impact of solvent residue on the battery's electrochemical performance.

Key Factors Affecting Slurry Quality

Solid Content Control: The proportion of solid components in the slurry needs to be strictly controlled. Excessively high solid content leads to poor fluidity, while too low a content impacts the coating efficiency.

Stirring Intensity and Time: Stirring speed and time determine the degree of particle dispersion and slurry stability. High-speed shear stirring equipment is commonly used.

Viscosity Adjustment: The viscosity of the slurry is adjusted by controlling the binder amount or solvent ratio to meet the requirements of the subsequent coating process.

Slurry Preparation Process

Dry Pre-mixing: Initially mix the active material, conductive agent, and binder using dry methods.

Wet Dispersion: Add the appropriate solvent and stir vigorously to fully wet and disperse the materials.

High-Speed Shear Treatment: Use high-speed dispersing machines or bead mills to further refine the particles and enhance uniformity.

Slurry Filtration and Degassing: Remove impurities and gas bubbles to improve the quality of the slurry.

Types of Slurry Preparation Equipment

Common industrial slurry preparation equipment includes planetary mixers, twin-screw extruders, and high-speed dispersers. Different equipment is suited for different material systems and production capacity requirements. For example, planetary mixers are suitable for preparing high-viscosity slurries, while high-speed dispersers are ideal for rapid homogenization.

Slurry Quality Testing Methods

To ensure the consistency of the slurry, various tests are conducted, including viscosity tests, solid content measurement, particle size distribution analysis, and electron microscopy observation. The rheological properties of the slurry must also be assessed to ensure its compatibility with automated coating equipment.

The coating process is a critical step in the production of lithium battery cells, primarily involving the uniform application of positive and negative electrode materials onto metallic foil substrates. Yilai Power offers integrated process solutions to help companies optimize their production processes.

Coating Process Flow

Slurry Preparation: Mix the active material, conductive agent, and binder in specific proportions and add a solvent to form a uniform slurry.

Coating Operation: Use methods such as scraping, spraying, or roller coating to apply the prepared slurry uniformly onto aluminum foil (positive electrode) or copper foil (negative electrode).

Drying: After coating, the layer must be dried to remove the solvent, typically using hot air circulation drying.

Compression: The dried electrode sheets are compressed using rolling equipment to ensure strong adhesion between the coating and the current collector.

Key Technical Parameters

Coating Thickness Control: Precision should be within ±1μm.

Solvent Residue After Drying: Should be ≤50ppm (measured by gas chromatography), with coating adhesion ≥0.5N/cm (3M tape peel test, with a detachment area ≤5%).

Solid Content Control: Typically controlled between 40%-70%.

Drying Temperature and Time: Must be strictly controlled to prevent coating cracking or bubble formation.

The calendering and slitting processes are critical stages in the production of lithium battery cells, directly affecting the battery's performance, safety, and consistency.

Calendering Process

After the coating is applied, the electrode sheets undergo calendering. The primary purpose of calendering is to improve the bonding strength between the active material and the current collector while controlling the thickness and density of the electrode sheets. The roller press applies pressure to both the positive and negative electrode sheets, making the coating more uniform and dense, thereby improving the energy density and cycle life of the battery.

Positive Electrode Density Control: For ternary materials, the density should range from 3.5-4.2g/cm³, and for lithium iron phosphate, it should be 2.2-3.0g/cm³ (excessively high density can hinder ion conductivity, while too low density results in insufficient energy density). During the calendering process, parameters such as pressure, speed, and temperature must be strictly controlled to avoid cracking or delamination of the electrode sheets.

Slitting Process

Slitting takes place after calendering, with the purpose of cutting large electrode sheets into the required dimensions and shapes. High-precision slitting machines are used to cut the sheets according to design specifications, ensuring that the edges are smooth and free from burrs. During the slitting process, care must be taken to avoid generating metallic dust, which could affect the internal structure of the battery or cause short circuits. After slitting, the electrode sheets are subjected to quality testing, including width, thickness, and edge alignment checks.

The winding process is a critical step in the manufacturing of lithium battery cells, directly impacting the battery's performance, capacity, and safety.

Electrode Preparation

Positive and negative electrode materials are applied to current collectors (such as aluminum foil or copper foil), followed by drying and calendering to ensure the active materials are evenly distributed and adhere strongly. After coating, the electrode sheets are cut into the specified width.

Electrode Cutting and Punching

Specific notches or holes are made in the welding areas of the electrode sheets using die-cutting or punching methods to facilitate welding with external current collectors. After cutting, edge burrs (≤5μm) must be treated to prevent them from puncturing the separator and causing short circuits. The punched areas must align precisely with the welding areas of the tabs to ensure uniform current conduction.

Winding Process

The positive electrode sheet, separator (typically polyethylene PE separator with a thickness of 8-12μm and a porosity of 40%-50%), and negative electrode sheet are stacked and fed into the winder. The winding equipment tightly coils these components into cylindrical or elliptical structures, with alignment deviations of positive and negative electrode sheets ≤0.3mm and separator edge width ≥2mm (to prevent short circuits).

Thermal Pressing and Shaping

The wound battery core, which may appear slightly loose, is pressed through a thermal pressing device to give it a stable geometric shape and enhance interlayer adhesion.

Tab Welding and Packaging

The tabs of the wound core are welded to the external connection tabs on the casing or top cover. After welding, the cell enters the packaging stage, where electrolyte is injected, and the cell is sealed to complete the initial assembly.

Formation and Aging Test

The assembled cell undergoes an initial charging process (formation) to activate the internal chemical reactions, followed by aging tests to filter out unstable cells, ensuring consistent quality for the final product.

Core Technological Advantages

The core technology of soft pack lithium batteries lies in balancing "flexibility" and "stability". By alternately stacking positive and negative electrode sheets with separators in a Z-shape, space utilization is maximized. High-voltage insulation testing (Hi-pot) and short-circuit testing ensure safety, ultimately achieving an optimized balance between energy density and cycle life.

Yilai Power employs a "Z-shaped stacking + high-precision winding" process combination, which controls the consistency deviation of soft pack batteries within ±2% (better than the industry average). The aluminum-plastic film features a 0.15-0.2mm three-layer structure, with precise molding depth matching the battery cell dimensions to reduce the risk of leakage.

Typical Application Scenarios

Consumer Electronics: Soft pack batteries with ultra-thin designs (0.5mm) are used in micro-devices like smartwatches and Bluetooth headphones, with a capacity density of up to 700Wh/L. They are adaptable to irregular structural designs.

Energy Storage: Household energy storage batteries made from 50Ah soft pack cells offer a cycle life of over 3000 cycles (at 80% DOD), meeting long-term storage requirements for home use.

Portable Devices: Drones, laptops, and similar devices utilize high-capacity soft pack batteries, which are 15%-20% lighter than square-shaped batteries of the same specifications, enhancing their endurance.

Soft pack lithium batteries, with their high safety and flexible design advantages, continue to expand their application prospects in the renewable energy sector. The precision of their manufacturing process directly determines their performance boundaries—from slurry particle dispersion to inter-layer alignment during winding, every step must balance technological detail with production stability.

Yilai Power has refined its processes over many years and has achieved comprehensive process control, from material selection to final product testing. The precision of key equipment is maintained within ±0.01mm, with core performance indicators ranking among the top in the industry.

In the future, we will continue to optimize slurry preparation processes (such as exploring dry electrode technology), adapt solid-state electrolytes, and focus on other cutting-edge technologies. This will further enhance the consistency and cycle life of soft pack batteries and drive their large-scale application in a wider range of scenarios.

For more details on our processes or custom solutions, visit our official website at www.yilaipower.com, or contact our technical team for exclusive solutions.