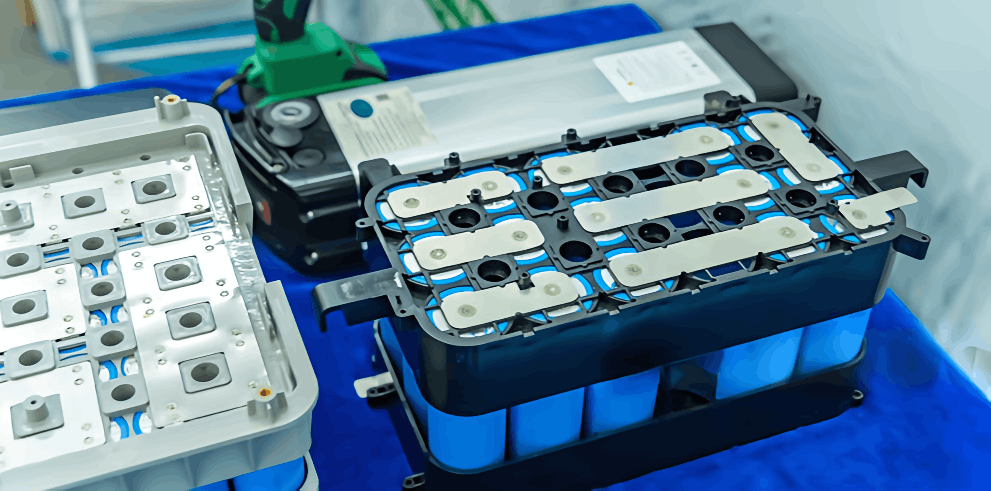

Lithium iron phosphate (LiFePO₄) batteries, as an efficient and safe energy storage solution, have gained global popularity in recent years. They stand out with unique chemical properties: using lithium iron phosphate as the cathode material, they offer higher thermal stability (less prone to thermal runaway at high temperatures), longer cycle life (typically over 1,500 cycles), a wider operating temperature range (-20℃ to 60℃), and contain no scarce metals like cobalt or nickel, resulting in lower cost volatility and better environmental friendliness. These features make them ideal for home energy storage, commercial floor scrubbers, industrial sweepers, outdoor power supplies, low-speed electric vehicles, and other scenarios.

For buyers, balancing performance and cost is the core challenge. This article provides a "cost-effective procurement guide" tailored to LiFePO₄ battery characteristics, with a focus on European and American market needs, combining practicality and professionalism.

The economy of purchasing LiFePO₄ batteries is not about pursuing the lowest price blindly, but matching battery performance precisely to usage scenarios. Blind price-cutting may lead to:

• Capacity mislabeling (actual capacity deviates by over 20% from the marked value)

• Shorter cycle life (attenuation rate far exceeds expectations in actual use)

• Insufficient safety margins (lack of necessary protective designs)

Therefore, clarify three key dimensions before purchasing:

Application Scenarios: Home energy storage (focus on capacity stability), industrial equipment (requires tolerance for high-frequency charging/discharging), outdoor mobile devices (emphasize weight and vibration resistance).

Core Parameters: Voltage (must match equipment motors or inverters), capacity (determines single-charge runtime), charge/discharge rate (affects fast-charging speed and instant power).

Usage Cycle: For short-term turnover (e.g., rental equipment), initial costs can be controlled appropriately; for long-term use (e.g., fixed energy storage systems), prioritize total cost advantages from long cycle life.

The cost of LiFePO₄ batteries is closely tied to production scale. Standardized cells (e.g., 32140, 32700 LiFePO₄ cylindrical cells) have lower base costs due to mass production advantages. For special equipment (e.g., custom-sized cleaning machines, energy storage cabinets), customized solutions can reduce overall system costs by optimizing structure to improve space utilization.

• Example: A commercial floor scrubber manufacturer used standard cells to customize 24V battery packs, saving 15% installation space and reducing per-unit battery costs by 8% compared to universal modules.

• Recommendation: Prioritize standardized products when basic parameters (voltage, capacity) meet general standards; choose customization for devices with special size or interface requirements to maximize performance.

LiFePO₄ battery prices, influenced by raw materials (lithium, iron, phosphorus) and market demand, follow distinct seasonal patterns:

• Low seasons: March-April and September-October annually (post-holiday demand declines, manufacturers often offer discounts), with prices 10%-15% lower than peak seasons.

• Pitfalls to avoid: Winter (November-February) is the peak season for energy storage equipment procurement, leading to tight supply and potential price premiums; policy shifts (e.g., subsidy adjustments) may also cause fluctuations. Plan purchases in advance.

• Bulk purchases yield better prices for both standardized modules and customized solutions, with significant cost reductions for larger orders.

• Example: For 12V 100Ah modules, the unit price is approximately $125 (approx. 900 RMB) for orders under 100 units, and can drop below 800 RMB for 500+ units.

• Flexible options: Customers with assembly capabilities can purchase bare cells + independent BMS for self-assembly, saving 20%-25% compared to finished modules (note: assembled products must pass safety tests).

In long-term use scenarios, "cost per kWh" and "cost per cycle" better reflect true cost-effectiveness. Formula:

Cost per kWh per cycle = (Total battery price ÷ Expected cycles) ÷ Capacity (kWh)

• Example:

◦ Battery A: 1,000 RMB, 1,000 expected cycles, 1kWh capacity → 1 RMB/kWh per cycle

◦ Battery B: 1,500 RMB, 3,000 expected cycles, 1kWh capacity → 0.5 RMB/kWh per cycle

Although Battery B has a higher initial investment, it is more cost-effective for long-term use.

After defining procurement strategies, verifying product quality is crucial. Here are three non-negotiable quality standards:

High-quality batteries should have a monomer voltage difference (in static state) of ≤ 0.05V. A difference exceeding 0.1V indicates poor cell sorting, which may cause local overcharging/over-discharging and accelerate attenuation.

• Testing method: Randomly sample 3-5 battery packs during procurement, measure single-cell voltages with a multimeter (0.01V precision), and record the maximum difference.

Reputable manufacturers provide factory cycle test reports (e.g., cycles at 1C charge/discharge to 80% capacity) instead of just "theoretical values."

• Industry reference: Qualified LiFePO₄ batteries should retain ≥ 80% capacity after 1,000 cycles at 1C; high-quality products can exceed 2,000 cycles (factory-tested data is the primary reference).

BMS (Battery Management System) is critical for safety. Low-cost batteries with omitted or simplified BMS significantly increase risks. Confirm BMS includes:

• Overcharge protection: Automatically cuts off power when cell voltage ≥ 3.6V

• Over-discharge protection: Automatically cuts off power when cell voltage ≤ 2.5V

• Over-temperature protection: Activates cooling or power-off when battery temperature ≥ 60℃

(Note: Parameters can be adjusted based on equipment needs; confirm customization details with manufacturers.)

As a professional manufacturer, Yilai Technology offers highly cost-effective solutions for global customers through a "standardization + customization" dual model:

• Full range of standardized modules: 12V/24V/48V modules based on mature cells like 32140, with 1,500-2,000 cycles (factory-tested, retaining 80% initial capacity). UL, CE certified, compatible with mainstream European and American equipment, with bulk prices 8%-12% lower than market average.

• Flexible customization: Supports battery pack customization based on equipment size, voltage, and power requirements. Short lead time from design to mass production (15-20 days), with customized products sharing the same scaled supply chain as standardized ones for significant cost advantages.

Yilai Technology has a complete production and testing system. All batteries undergo strict factory tests (charge/discharge cycles, high-low temperature environments, vibration impact, etc.) and come with a 2-year warranty. Serving over 50 customers in European and American markets, we balance cost and reliability.

LiFePO₄ batteries excel in scenarios demanding safety and long cycle life (e.g., energy storage, low-speed vehicles); ternary lithium batteries, with higher energy density, suit range-sensitive scenarios (e.g., passenger cars).

No. Customization only adjusts cell arrangement and casing structure; core cells are identical to standardized products. With tailored BMS parameter optimization, lifespan matches that of standardized products.

Request production batch reports from manufacturers (including cell production dates and test records); new cells have no signs of polishing/refinishing, unoxidized/uncolored tabs, intact packaging, and clear labels.

The key to purchasing cost-effective LiFePO₄ batteries lies in "clarifying needs + verifying core indicators + choosing reliable manufacturers." As a source manufacturer, Yilai Technology offers both cost-effective standardized products and customized services to meet special needs. Contact us for exclusive quotes and solution design support.